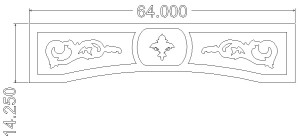

Our customer has requested a fireplace header with a fleur de lis in the center and a flourish on each side. The piece will measure 64” x 14 ¼” x 1 ½”. The header will be painted so we will use ¾” composite board for our components. The components will consist of a base, a band and 3d objects. The band and the 3D objects will stack on top of the base.

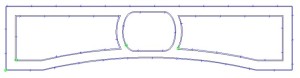

We did the initial layout in our EnRoute software program.

The base will be scored with a 60 degree conic bit to reference the location of our 3D objects and band.

The base and band were cut out using a 3/8” compression bit.

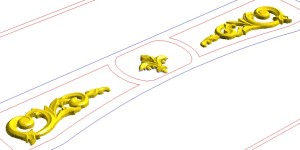

We created a flat relief and merged the 3 dimensional mesh objects …the fleur de lis and the flourishes. These pieces will be machined with a ¼” ball nose bit and cut out of the material with a ¼” end mill.

The files were sent to our MultiCam 5000 for machining…total machine time required…1 hour.